In Vacuum CNC we specialize in the manufacture of clamping blocks and other cnc clamping solutions for the wood working industry. We have been working throughout all these years in unifying in our brand all the subjection systems by vacuum for mechanising centres that exist in the market right now. Moreover, we have added certain improvements to work easily and help out in the saving of our clients.

The best Vacuum Pods in the market

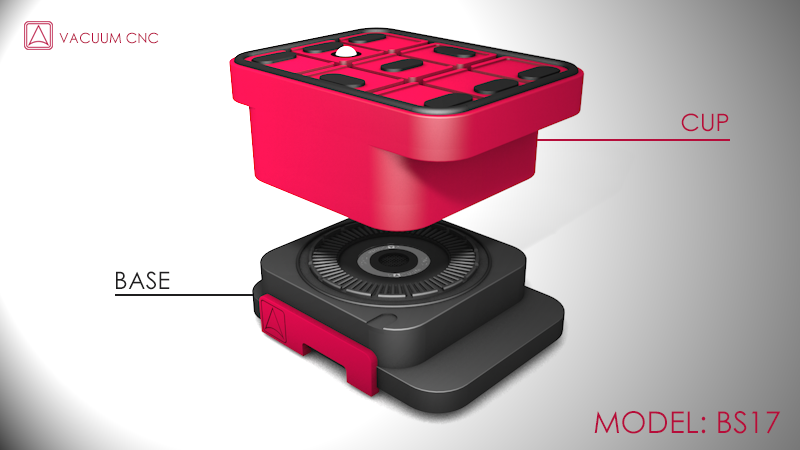

By separating the original clamping block in two parts (Base and Cup) we have achieved the best vacuum pod in the market. This division offers quite huge advantages:

- Easy and fast to exchange the suction area.

- All the cups turn 360 degrees staying fixed when turning on the vacuum.

- It allows us to work at many different heights:

- By fixing intermediate lifters between the base and the cup.

- By placing cups of different heights.

- All of the vacuum cups have touch valve, so we can hold the vacuum block on the table even if they do not need to be used without losing vacuum.

- It allows, in case of a broken cup or need of a new suction area, to replace only the cup, what leads to a significant economic saving.

- The cups enclose the superior vacuum by a sealing rubber, very affordable and easy to replace. If It gets broken (until a 7 mm depth) we can fix the vacuum cup at 100% of its capacity simply by changing the damaged gum part.

- For enterprises that have more than one mechanising centre with different vacuum cups, thanks to our system in two pieces it could be studied the point of combining the heights so that we can use the same cups in both milling centres (sometimes it may be necessary to change the height in which it works, otherwise, the combination is not possible).

- For the majority of models it exists the cup system with board lifter included. It exists for both formats, the vacuum system and the compact one.

Cnc clamping solutions for door jambs

Vacuum-cnc launches its patented door jamb clamp, where it has achieved what is sometimes more difficult, developing a simple and effective system at the same time. With maximum work efficiency, it provides another fundamental aspect, the ease of assembly and disassembly, which makes both the making of the door jambs and their preparation not a great effort for you, nor does it leave the machine partially blocked as it happens with other clamping systems. Activated by the vacuum of the machine, it does not need to have any type of external setting-up.

Mechanical Presses or Clampers

Vertical mechanical clampers activated by vacuum. They turn on when activating the vacuum in the machine and they position as any other kind of vacuum cup, without hose connection or screws unless is absolutely necessary. In addition, clamping forces of up to 700 N. All of our vertical presses include two elevator caps of 25 and 50 mm for being able of lifting the height, until a recommended maximum of 100 mm, allowing us to realize all kind of tasks.

We have a wide catalog of mechanical presses, and all of them function with vacuum. You can search here the best mechanical press for you machine.

See more in our YouTube channel.

In case you need to clamp very small pieces, we have the best solution for you: our Horizontal Mechanical Press.

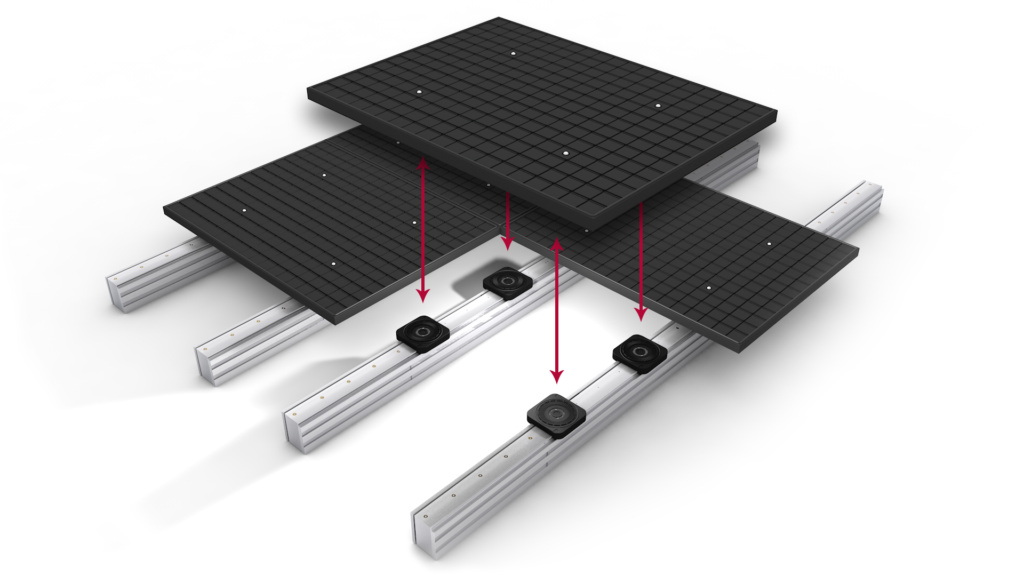

The Nesting Module

We have designed and developed a new improved system to turn your cnc machine into a grid table. This solution works just by placing our nesting module on your Vacuum-cnc bases. When held by the crowns of the bases, a better grip on the machine is achieved.

The Panel lifter

The panel lifter is an alternative model of our Vacuum cnc cups. We want to have a cohesive and relational system. Therefore, you can couple it to the different bases as any other kind of our cups. We have designed it to lift the wood, or the piece you are working on, when you turn off the vacuum, in order to avoid any kind of scratch.

Vacuum Pumps and other products

Finally, we also sell other products like Vacuum Pumps or rubber replacements for our suction cups.

+34 91 059 94 83 – +34 682 77 19 34

+34 91 059 94 83 – +34 682 77 19 34